Summary of the Project

Unique Group completed two complex cable trenching project scopes involving the post-burial of 28mm fiber optic cable across three separate locations, covering a total distance of approximately 14.2 km and a post-burial of 23mm fiber optic cable to a depth of between 0.8 and 1.2 meters, over a distance of approximately 7.2km. The trenching was completed using the Uni-FlowX, Controlled Mass Flow Excavation system (CFE), under challenging weather conditions and tough seabed conditions.

Client Requirement

The client specified that the post-burial of the fiber optic cables needed to be performed in two locations in Malaysia, one was for approximately 14.2km and it needed to be buried in a trench at a depth of 1.5 meters while the second one was for approximately 7.2km at a depth between 0.8 and 1.2 meters. The project was particularly time-sensitive, requiring efficient execution due to the constraints we had to work around.

Challenges Faced

- Monsoon Season: The project was undertaken during the monsoon season, and we had to tackle unpredictable and severe weather conditions.

- Seabed Conditions: The seabed was extremely hard, making trenching operations difficult and slow.

- Underpowered DP1 Vessel: The dynamic positioning vessel available for the project was underpowered (DP1), limiting its operational capacity.

- Adverse Weather Conditions: The weather presented significant challenges with high swells and strong currents, exceeding the usual working conditions.

- Time Restraint: The client only permitted a single pass for the trenching operation

- Variable Trench Depth: Unforeseen seabed strengths along the cable route led to variations in trench depth. Given the challenging conditions, it was agreed with the client to adjust the minimum trench depth to maintain good progress.

Unique Solution Delivered

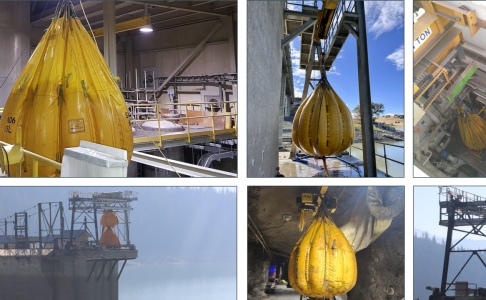

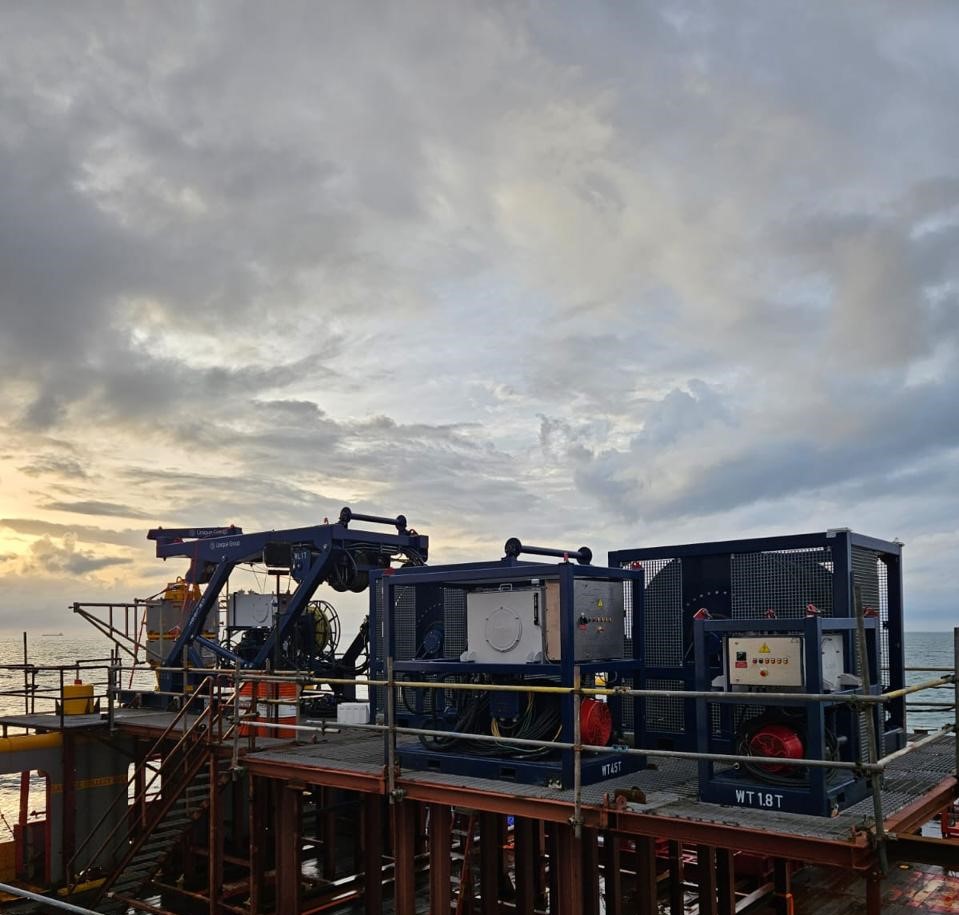

After an assessment of the client’s requirements by Unique Group’s technical team, our in-house developed Uni-FlowX, Controlled Mass Flow Excavation system (CFE) was deployed to complete the trenching operations as it is well suited to handle tough seabed conditions.

The Uni-FlowX’s water jetting system was used simultaneously with the Digger excavation to enable easier trenching and reduce the resistance of the seabed. We used dual multibeam sonars to provide precise mapping and depth measurements, ensuring accurate trenching and minimizing the risk of errors due to varying seabed conditions.

The first project covering 14.2km was divided into three sections:

- Section 1: Covered 5.6 km with an average trench depth of 1.0 to 1.5 meters.

- Section 2: Spanned 4 km with an average trench depth ranging from 0.5 to 1.5 meters.

- Section 3: Encompassed 4.6 km with an average trench depth of 0.5 to 0.9 meters.

For the second project for approximately 7.2km, the trenching was completed with an average depth of 1.0 to 1.5 meters, aligning with the adjusted client requirements. Screen grabs were taken every 10 meters to ensure consistent performance.

Benefits Delivered

- Efficient Trenching: Despite the challenging conditions, trenching was completed to the client’s requirements in all three sections, demonstrating the effectiveness of the Uni-FlowX equipment combined with the jetting spread and dual sonars.

- Enhanced Precision: The use of dual sonar heads ensured accurate depth measurements, enabling the team to adapt to the varying seabed conditions and meet the adjusted trench depth requirement.

- Operational Success: The equipment and technology allowed the project to be completed within the constraints of a single pass and under extreme weather conditions, fulfilling the client’s requirements effectively.

- Complete technical support: Unique Group’s technical team supported the client throughout the project to ensure a seamless execution.