Summary of the Project

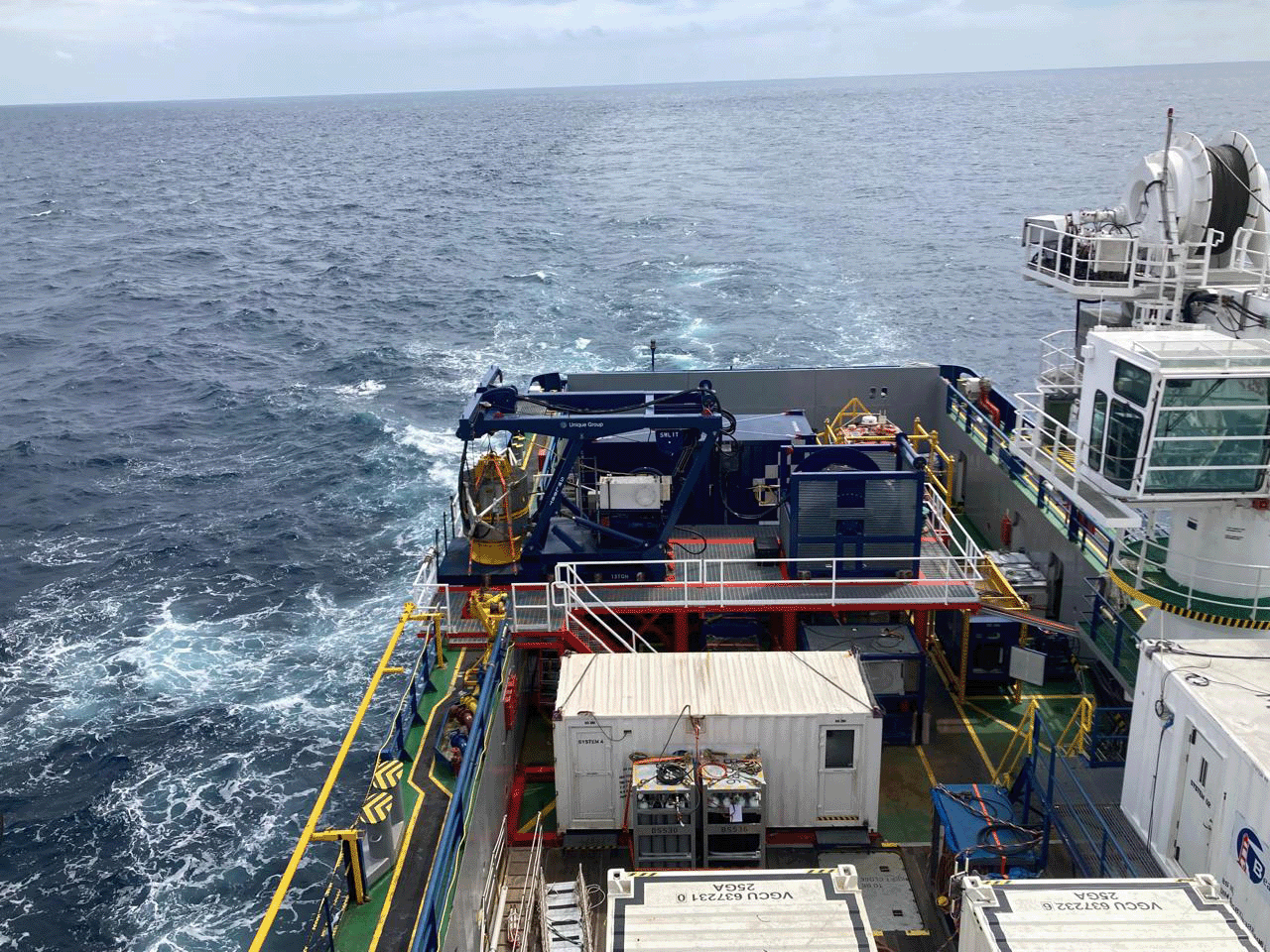

Unique Group’s Uni-FlowX CMFE (Controlled Mass Flow Excavation) equipment successfully supported our client with pipeline de-burial services aimed at preparing the pipeline segments for installation of repair clamps. The segments were spread over 10 locations and at a depth ranging from 10 to 60 meters.

Client Requirement

The client was looking for the Uni-FlowX CMFE system to clear and excavate clearance below the pipeline segments in preparation for the installation of repair clamps. The campaign involved multiple contractors working together at a time and the client expected high-level coordination and synchronization to complete the project timely and safely.

Unique Solution Delivered

After assessing the client’s requirements by Unique Group’s technical team, our in-house developed Uni-FlowX, CMFE system was deployed to complete the de-burial and excavation operations across 10 locations with water depths ranging from 10 to 60 meters.

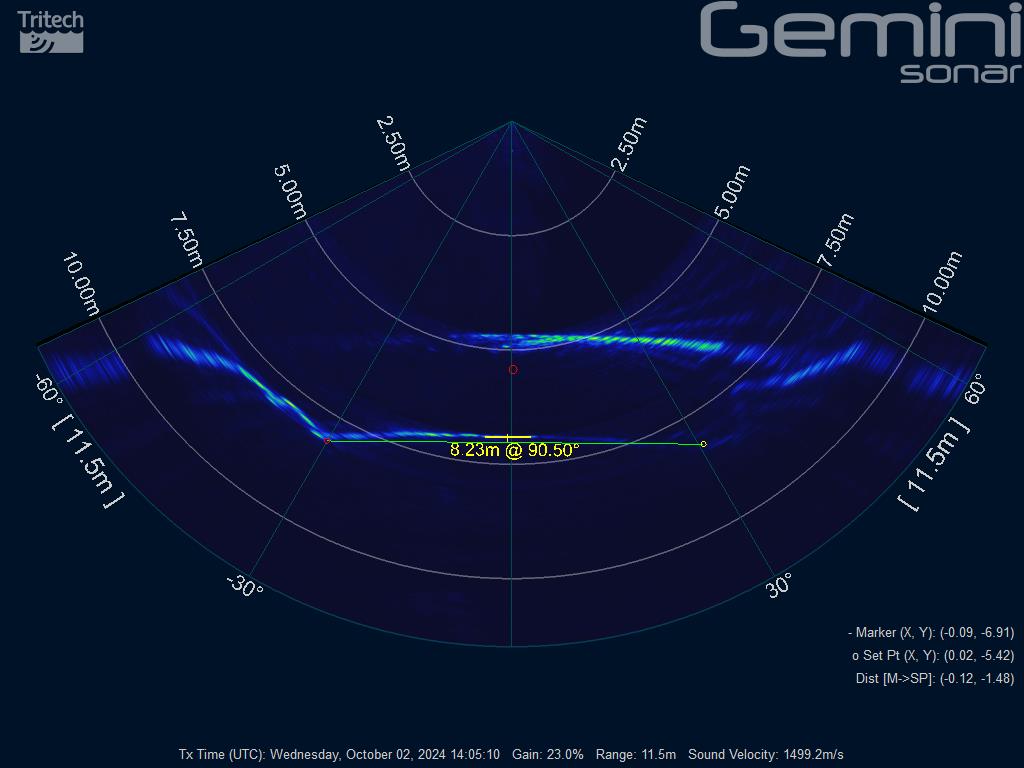

Uni-FlowX performed excavation operations to create box sections at all 10 locations, each box approximately 6mtr L x 8mtr W x 1.5mtr D.

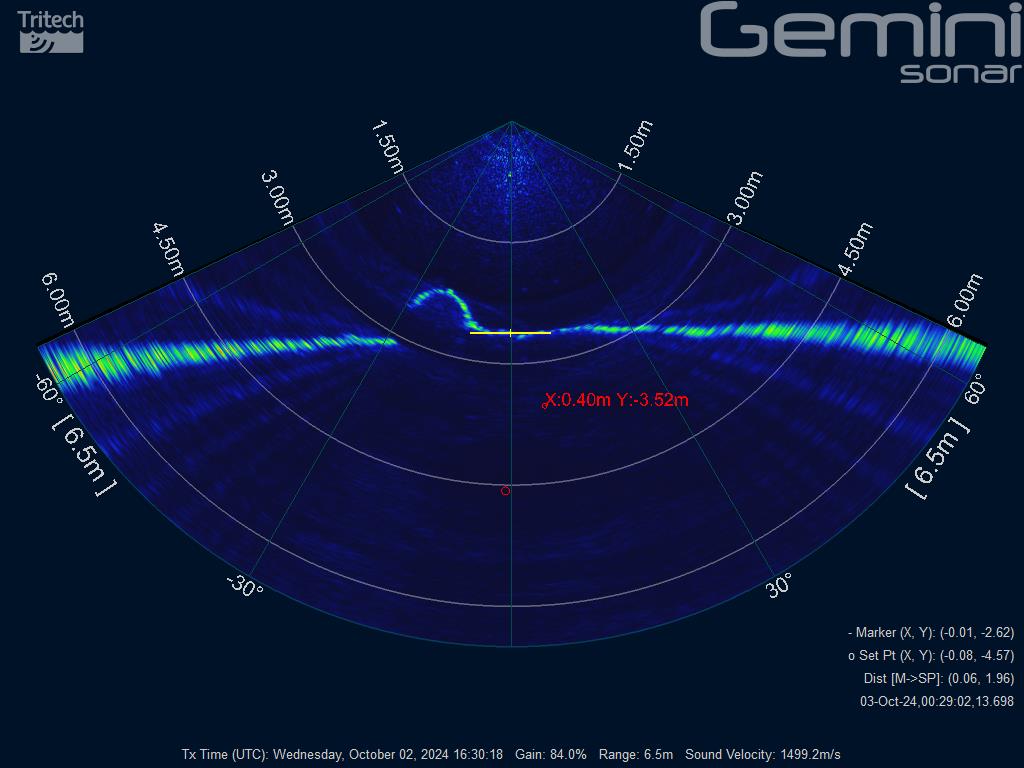

One Section of the pipeline for 64mtr L was buried and the Uni-FlowX tool was used to excavate and expose the crown of the pipeline so that the ROV can do a visual inspection and locate field joints.

We used dual Gemini multibeam sonars to provide precise mapping and depth measurements, ensuring accurate excavation was achieved. Each location was excavated to allow the concrete cutting tool and ROV access to the pipeline location where the repair clamp will be installed. Once all 10 locations were complete and concrete removed then the client was ready to install the repair clamps with divers on their next campaign.

Benefits Delivered

- Efficient Excavation: Excavation was completed to the client’s requirements in all sections, demonstrating the effectiveness of the Uni-FlowX equipment fitted with Gemini dual sonars.

- Enhanced Precision: The use of dual sonar heads ensured accurate measurements of the scope of work required.

- Operational Success: The equipment and technology allowed the project to be completed seamlessly, working cohesively with the client and all the other 3rd party contractors onboard to complete this campaign

- Complete technical support: Unique Group’s technical team supported the client throughout the project to ensure a seamless execution.

Client Feedback

“The Unique Group team was very professional and provided a service that was as advertised. They were efficient and more than happy to help and advise as needed.” – Superintendent from the client who worked with Unique Group on the project.