Client Name: Oceaneering

Unique Group is a leader in designing and manufacturing diving and life support equipment, we have a long and proud track record in the manufacture of classed saturation diving systems. We provide custom DSV saturation, portable and HRF saturation systems, while we also supply bell and chamber life support equipment and other key ancillary kit.

To know more, get in touch with us.

Summary of the Project

Unique Group successfully designed, manufactured and delivered a state-of-the-art 12-man Hyperbaric Reception Facility (HRF) and Life Support Package (LSP) for Oceaneering. This project supports a significant air and saturation diving operation, encompassing the transportation and installation phases of a field life extension initiative in Angola.

Client Requirement

The client required a compact, well-engineered Hyperbaric Rescue Facility (HRF) system to support safe manned diving operations at depths of up to 300 meters. The system needed to comply with DNV and IMCA guidelines while being modular and adaptable for future upgrades or downgrades based on operational requirements. The scope of supply required to include a comprehensive certification pack and a detailed range of components, ensuring seamless functionality and compliance with safety standards.

Challenges Faced

The primary challenges revolved around:

- Ensuring compliance with stringent DNV and IMCA guidelines while maintaining a compact and modular design.

- Integrating multiple components—such as the SPHL clamp, spool, and leveling table—into a seamless system while meeting the client’s safety and operational standards.

- Delivering a versatile system capable of rapid deployment and easy customisation for future needs.

Unique Solution Delivered

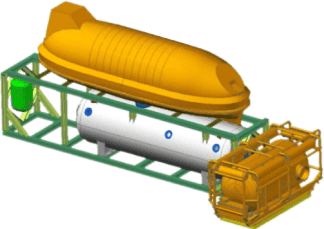

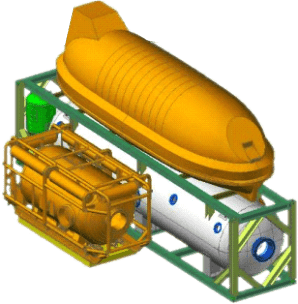

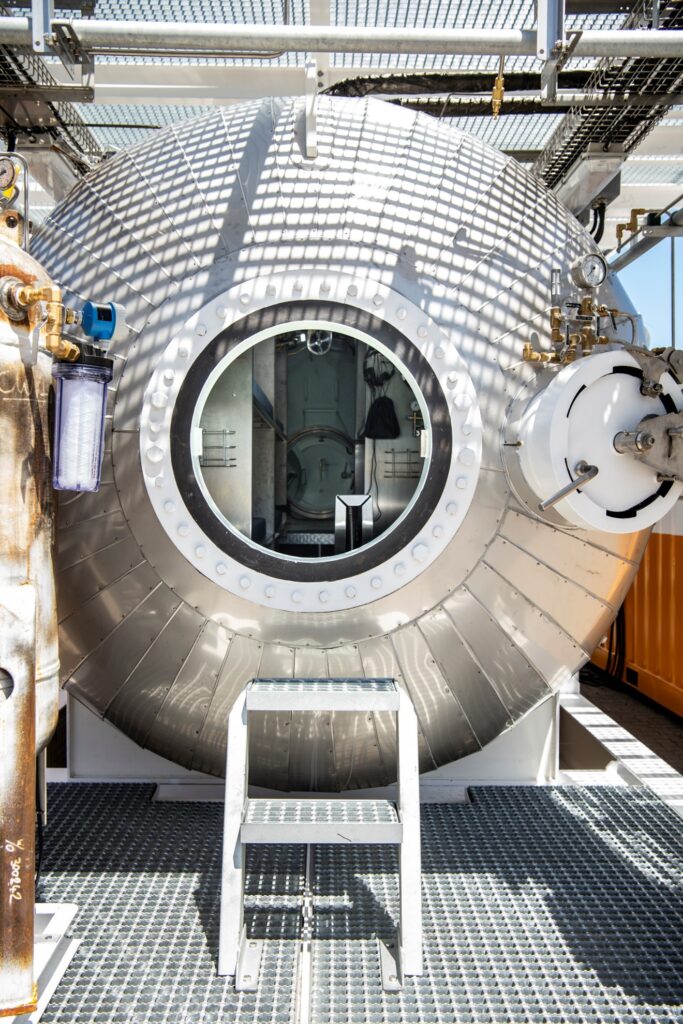

Unique Group supplied a state-of-the-art HRF system designed with modularity and safety as the core focus. The system included a 40ft DNV 2.7-1 chamber skid, featuring a 12-man Twin-lock HRF pressure vessel, SPHL support mechanisms, and interconnecting hoses and cables. The HRF chamber and life support container is designed and built to ensure safe manned diving pressures of up to 300 meters seawater depth.

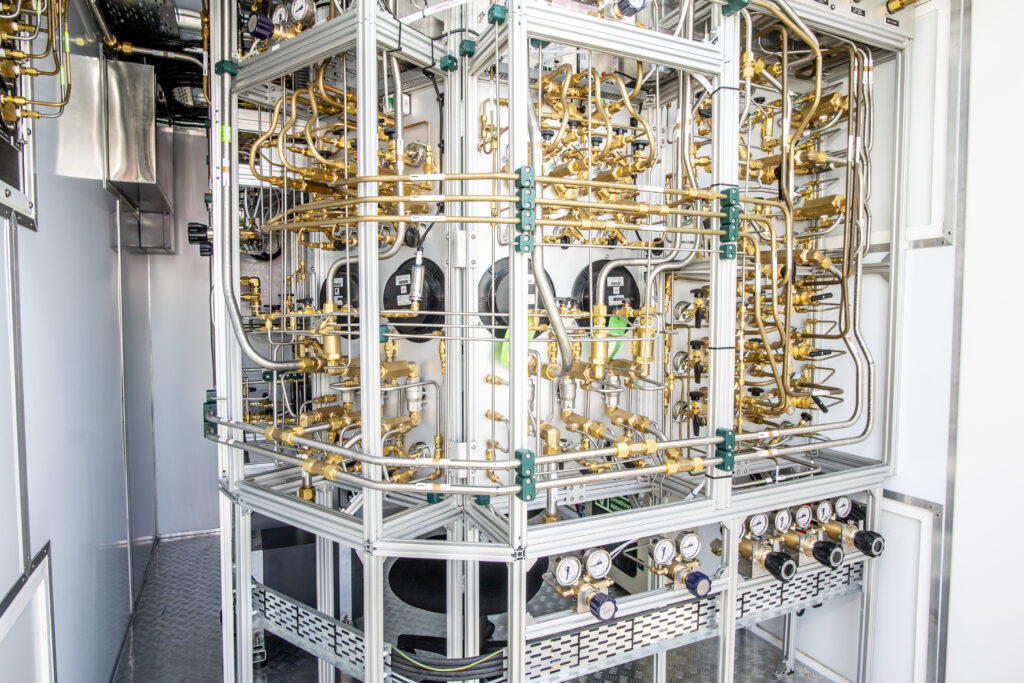

Two 20ft DNV 2.7-1 support containers were provided, housing both the control room and a machinery area. The control container is partitioned into two sections, where one section houses the HRF control room and is fully fitted with the necessary LSS gas panels and electrical control and monitoring systems to ensure safe HRF operations and the other section is fitted with a workshop room.

The second container is used for the HRF machinery, housing two chillers and a dual hot water unit, one potable water system with associated electrical reticulation. The remaining container space can be used as a storage area during transport.

The HRF system comprised:

- Main Lock (Lock 1): A Diving Medical Advisory Council (DMAC) compliant facility with berths, seating, a basin, and tiltable bunks.

- TUP (Lock 2): Equipped with ablution facilities, wet pot functions, and decontamination capabilities, enabling a seamless transition between the SPHL and the TUP.

- SPHL Spool and Clamp: Ensuring a secure transit route between SPHL and the decontamination lock.

- Machinery Container: Housing chillers, hot water units, potable water systems, and associated electrical systems.

The modular design facilitates future upgrades in a cost-effective and timely manner, ensuring long-term client satisfaction.

Benefits Delivered

- Safety Compliance: The system meets and exceeds DNV-OS-E402 and IMCA D053 guidelines, ensuring the highest safety standards.

- Operational Efficiency: Modular design allows the system to be easily adapted for different job requirements, minimizing downtime and ensuring quick deployment.

- Cost-Effectiveness: The modular approach enables future upgrades with minimal investment, reducing long-term operational costs.

- Enhanced Functionality: With dual-lock chambers and integrated SPHL and decontamination capabilities, the system provides comprehensive support for complex diving operations.

- Versatility: The HRF system’s transportable skid and support containers ensure flexibility for diverse operational environments.

- Designed-for-Comfort: Our chambers are designed for comfort; we understand that divers are attracted to return to vessels because of the dive system’s comfort and safety.

By delivering this sophisticated HRF system, Unique Group reinforced its reputation as a reliable, quality-focused manufacturer, ensuring clients have the tools needed for safe and efficient diving operations.

Client Name: Oceaneering

Unique Group is a leader in designing and manufacturing diving and life support equipment, we have a long and proud track record in the manufacture of classed saturation diving systems. We provide custom DSV saturation, portable and HRF saturation systems, while we also supply bell and chamber life support equipment and other key ancillary kit.

To know more, get in touch with us.