As offshore energy platforms reach end-of-life, safe and efficient dismantling is more important than ever. This article explores how Unique Group delivers end-to-end offshore decommissioning solutions—from advanced survey and diving systems to structure removal and innovative seabed excavation technologies like Uni-FlowX. Backed by 30+ years of experience, global engineering expertise, and trusted brands like Seaflex®, Unique Group helps operators streamline every phase of decommissioning while minimizing risk and environmental impact.

Key Takeaways

- Unique Group offers full-scope offshore decommissioning solutions, including equipment, services, and project management.

- Key capabilities include survey & inspection, diving systems, structure removal, and buoyancy solutions via Seaflex®.

- Proprietary technologies like Uni-FlowX enable safer, more efficient seabed excavation and debris removal.

- Proven track record with complex projects such as FPSO decommissioning for Lundin Tunisia.

- Services available for sale or rental, reducing CAPEX and simplifying vendor management.

As many offshore oil and gas platforms reach the end of their lifespan, the energy industry faces the complex task of decommissioning these structures. Operators are increasingly challenged with the complex and costly process of dismantling and safely disposing of them. However, emerging offshore decommissioning solutions—driven by advancements in technology, collaborative supply chain strategies, and specialized expertise—are driving down costs and improving efficiency.

Your One-Stop Shop for Offshore Decommissioning Needs

Unique Group is a global leader in providing integrated offshore decommissioning solutions to the energy industry. With a proven track record spanning over 30 years, we offer a fully integrated one-stop shop approach, supporting clients from project inception to completion. Our integrated approach not only covers advanced equipment and service delivery but also includes expert decommissioning project management to ensure seamless execution from inception to completion.

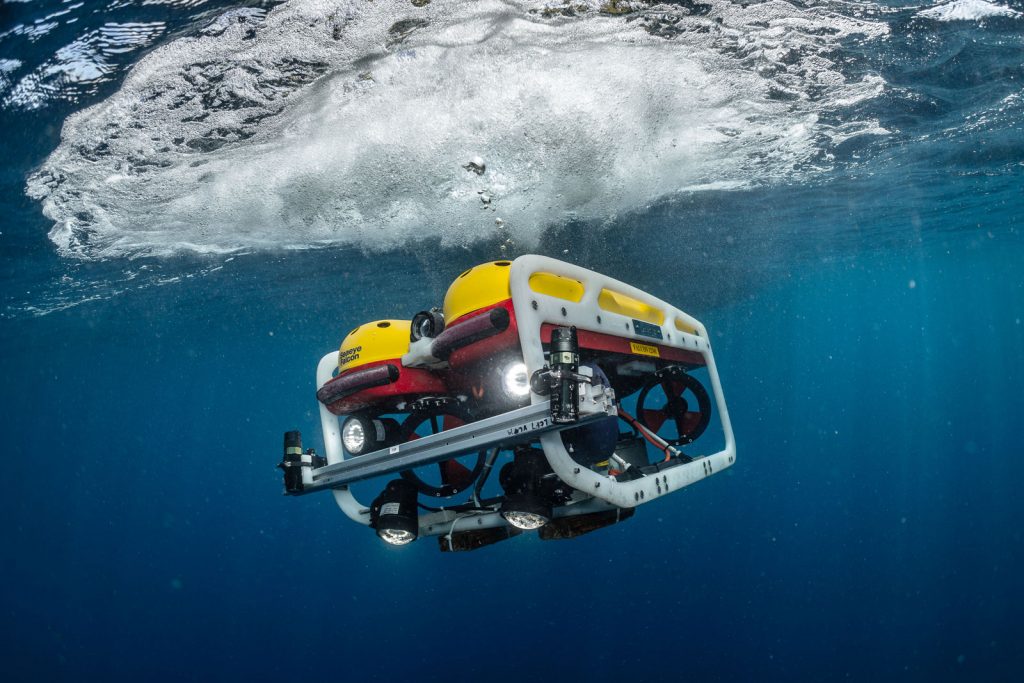

Our extensive portfolio encompasses a wide range of specialized services and equipment, with a recent investment of over 10 million USD in the latest survey technology. We excel in survey and inspection, offering advanced tools and technologies for site assessments, structural evaluations, pipeline inspections, and ROV operations. Our portfolio features renowned brands such as Kongsberg, Cygnus, Edgetech®, Nortek, and Saab Seaeye.

Our diving equipment division provides state-of-the-art solutions, including custom-built saturation diving systems and life support equipment. We provide a comprehensive range of IMCA-compliant and classed (Lloyds Register, ABS, DNV) diving equipment, including diver launch and recovery systems (LARS), decompression chambers, and containerised air and mixed gas diving systems.

To address the complex challenges of structure and debris removal, we offer cutting-edge recovery systems, seabed excavation & airlift, dredging capabilities, as well as specialized lifting and mooring equipment. These solutions are designed to safely and efficiently handle the removal of various offshore structures and subsea components.

To better understand each phase, see our detailed breakdown of the 7 key decommissioning stages here.

Unique Group also owns the renowned brand Seaflex®, which offers top-tier Air Lift Bags (ALBs) and other Buoyancy solutions essential for safe and efficient decommissioning projects. A notable example of our expertise is the decommissioning of a floating production storage and offloading (FPSO) unit for Lundin Tunisia. This complex project, conducted in approximately 300 meters of water and 80 km offshore, involved disconnecting moorings weighing several hundred tonnes. To reduce tension on the moorings, we installed 41 ALBs, each weighing up to 51 tonnes were installed.

Unique Group serves as a one-stop shop provider of offshore decommissioning equipment, offering a comprehensive range of assets for sale or rental. By consolidating equipment and services under one provider, we streamline the decommissioning process and enhances efficiency for operators.

Innovation at the forefront: Creating the tools you need

At Unique Group, innovation drives our approach to decommissioning. Our commitment to research and development is unwavering, as we believe in creating cutting-edge solutions to address the industry’s most complex challenges.

With a team of over 250+ engineering specialists and manufacturing facilities across the UAE, UK, and South Africa, we have the expertise and resources to design and build bespoke technology and equipment. Our philosophy is simple: if the tools don’t exist, we create them.

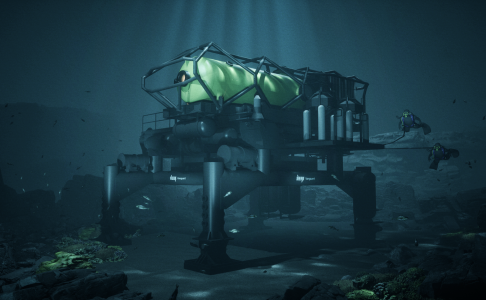

A prime example is our Uni-FlowX Controlled Mass Flow Excavation system. After years of research and development, we introduced this advanced technology , which significantly enhances seabed excavation. By eliminating physical contact with the seabed, Uni-FlowX significantly reduces risk, improves efficiency, and delivers unparalleled performance. This system, a prime example of our decommissioning technology innovations, recently played a crucial role in completing two complex cable trenching projects in Malaysia, overcoming challenging weather and seabed conditions.

Through close collaboration with clients and suppliers, our R&D department identifies and addresses specific needs, resulting in tailored and sustainable solutions for subsea operations.

By: Chris Forde, Executive Vice President – Eastern Hemisphere at Unique Group. This article was also published in the Subsea & Offshore Service Magazine.