Load testing is essential to ensure the safety, performance, and compliance of lifting equipment across industries like ports, shipyards, power plants, and marine operations. This article explains the most common types of load testing—such as proof load, dynamic, water bag, dead weight, static, load cell, and non-destructive testing—along with where and why each is used. Unique Group brings decades of expertise in delivering certified load testing solutions globally, supported by trusted technologies like Water Weights®. In this article, we explore how the load testing process is applied across different sectors to meet operational and safety standards.

Key Takeaways

- Load testing ensures the safety, reliability, and compliance of lifting equipment across sectors like ports, shipyards, mobile boat hoists, and power plants.

- Common methods include Proof Load, Dynamic Load, Water Bag (Water Weights®), Dead Weight, Static Load, Load Cell, and Non-Destructive Testing (NDT).

- Each method serves a specific operational purpose—from simulating dynamic load behavior to validating structural integrity.

- Unique Group offers decades of experience and customized guidance for asset-specific load testing requirements.

Load testing process play a critical role in ensuring the safety, reliability, and compliance of lifting equipment across industries like ports, ships, mobile boat hoists, and power plants. These essential procedures help verify how cranes, hoists, and load-bearing structures perform under specific weight conditions—preventing failures, accidents, and costly downtime. In this article, we explore some of the most common load testing process used across key sectors.

Proof Load Testing: This test involves loading equipment with a specified percentage of its maximum rated capacity, usually between 1.1 to 1.5 times the working load limit. It demonstrates the equipment’s ability to handle loads safely without permanent deformation or failure. For example, in ports and shipyards, cranes or lifting slings are subject to proof loads to ensure they can handle heavy cargo without issues.

Dynamic Load Testing: Dynamic load testing assesses how lifting equipment performs under moving or fluctuating loads. This method benefits ships, mobile boat hoists, and power plants. It simulates actual operational conditions, testing how cranes or hoists react to different speeds, directions, and types of loads. Dynamic tests help identify how mechanical components will hold up in dynamic environments, ensuring stability and safety.

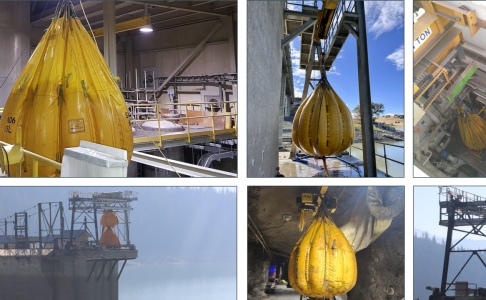

Water Bag Testing (Water Weights®): For large lifting equipment, water bag testing is preferred in ports, ships, and power plants. Water-filled bags simulate heavy loads and offer a flexible, cost-effective, and environmentally friendly option. These water bags can be precisely filled to specific weights and provide a controlled means of testing, making them ideal for cranes, davits, and mobile boat hoists. Due to their precision and safety,

Unique Group’s Water Weights® are often used in these applications

Dead Weight Testing:

Dead Weight Testing: In power plants, ports, and shipyards, dead weight testing involves physically loading equipment with fixed, non-moving weights, such as concrete or metal blocks. This traditional testing method ensures that lifting devices like cranes and hoists can handle maximum load capacities under stable, controlled conditions. While effective, this method is logistically more complex due to the need for handling physical weights.

Static Load Testing: This method evaluates equipment by applying a constant load over a sustained period. Static load testing checks the structural integrity of cranes, hoists, and other lifting gear in ports and shipyards. In power plants, static testing ensures that heavy-duty overhead cranes used for turbine or generator maintenance can support loads for long periods without deformation or structural damage.

Load Cell Pull Testing: Load cells are used across industries to measure force and weight during load testing. In mobile boat hoists, ports, and power plants, load cells are placed on hooks, slings, or lifting gear to measure the force applied during lifting operations. Load cell testing offers real-time data, making it highly accurate and reliable for ensuring equipment operates within safe load limits. In the case of pull testing, the load cell is anchored onto the deck or nearby structure, usually by shackles, wire rope, or slings, and pulled to achieve the required load.

Non-Destructive Testing (NDT): Non-destructive testing methods, such as magnetic particle or ultrasonic testing, are used alongside load testing in power plants, ports, and mobile boat hoists. These methods identify flaws, such as cracks or weaknesses in metal structures, without damaging the equipment. It’s a valuable supplement to load testing, ensuring no underlying defects even after a successful test.

The choice of load testing method depends on the specific operational requirements of each industry, from ports handling heavy cargo to power plants maintaining critical infrastructure. Each technique provides a layer of safety and assurance, ensuring that lifting equipment performs reliably under expected loads while adhering to regional regulations.

As pioneers of load testing with over three decades of expertise, our technical experts can provide technical guidance if you are looking for specific solutions related to load testing of your assets.

Contact us and choose the best solution for your requirements.

This article has been written by Jim Jota (Marketing Manager, Water Weights).

Need a Trusted Partner for Your Next Project?

Our multidisciplinary teams deliver reliable solutions across survey, diving, lifting, and engineering — ensuring success from concept to completion.

Dead Weight Testing: In power plants, ports, and shipyards, dead weight testing involves physically loading equipment with fixed, non-moving weights, such as concrete or metal blocks. This traditional testing method ensures that lifting devices like cranes and hoists can handle maximum load capacities under stable, controlled conditions. While effective, this method is logistically more complex due to the need for handling physical weights.

Static Load Testing: This method evaluates equipment by applying a constant load over a sustained period. Static load testing checks the structural integrity of cranes, hoists, and other lifting gear in ports and shipyards. In power plants, static testing ensures that heavy-duty overhead cranes used for turbine or generator maintenance can support loads for long periods without deformation or structural damage.

Load Cell Pull Testing: Load cells are used across industries to measure force and weight during load testing. In mobile boat hoists, ports, and power plants, load cells are placed on hooks, slings, or lifting gear to measure the force applied during lifting operations. Load cell testing offers real-time data, making it highly accurate and reliable for ensuring equipment operates within safe load limits. In the case of pull testing, the load cell is anchored onto the deck or nearby structure, usually by shackles, wire rope, or slings, and pulled to achieve the required load.

Non-Destructive Testing (NDT): Non-destructive testing methods, such as magnetic particle or ultrasonic testing, are used alongside load testing in power plants, ports, and mobile boat hoists. These methods identify flaws, such as cracks or weaknesses in metal structures, without damaging the equipment. It’s a valuable supplement to load testing, ensuring no underlying defects even after a successful test.

Dead Weight Testing: In power plants, ports, and shipyards, dead weight testing involves physically loading equipment with fixed, non-moving weights, such as concrete or metal blocks. This traditional testing method ensures that lifting devices like cranes and hoists can handle maximum load capacities under stable, controlled conditions. While effective, this method is logistically more complex due to the need for handling physical weights.

Static Load Testing: This method evaluates equipment by applying a constant load over a sustained period. Static load testing checks the structural integrity of cranes, hoists, and other lifting gear in ports and shipyards. In power plants, static testing ensures that heavy-duty overhead cranes used for turbine or generator maintenance can support loads for long periods without deformation or structural damage.

Load Cell Pull Testing: Load cells are used across industries to measure force and weight during load testing. In mobile boat hoists, ports, and power plants, load cells are placed on hooks, slings, or lifting gear to measure the force applied during lifting operations. Load cell testing offers real-time data, making it highly accurate and reliable for ensuring equipment operates within safe load limits. In the case of pull testing, the load cell is anchored onto the deck or nearby structure, usually by shackles, wire rope, or slings, and pulled to achieve the required load.

Non-Destructive Testing (NDT): Non-destructive testing methods, such as magnetic particle or ultrasonic testing, are used alongside load testing in power plants, ports, and mobile boat hoists. These methods identify flaws, such as cracks or weaknesses in metal structures, without damaging the equipment. It’s a valuable supplement to load testing, ensuring no underlying defects even after a successful test.

The choice of load testing method depends on the specific operational requirements of each industry, from ports handling heavy cargo to power plants maintaining critical infrastructure. Each technique provides a layer of safety and assurance, ensuring that lifting equipment performs reliably under expected loads while adhering to regional regulations.

As pioneers of load testing with over three decades of expertise, our technical experts can provide technical guidance if you are looking for specific solutions related to load testing of your assets. Contact us and choose the best solution for your requirements.

This article has been written by Jim Jota (Marketing Manager, Water Weights).

The choice of load testing method depends on the specific operational requirements of each industry, from ports handling heavy cargo to power plants maintaining critical infrastructure. Each technique provides a layer of safety and assurance, ensuring that lifting equipment performs reliably under expected loads while adhering to regional regulations.

As pioneers of load testing with over three decades of expertise, our technical experts can provide technical guidance if you are looking for specific solutions related to load testing of your assets. Contact us and choose the best solution for your requirements.

This article has been written by Jim Jota (Marketing Manager, Water Weights).